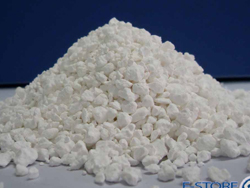

In the search for an effective solution to handle a wide variety of drying needs, science has come up with the use of calcium chloride or CaCl2. This compound comprised of calcium and chlorine has a number of benefits as a drying agent, and it has the useful quality of remaining in solid form in room temperature.

OCalcium chloride is often used in the process of manufacturing the desiccant drying tubes commonly used in packaging. For this particular application, calcium chloride drying agent is typically applied onto kelp, which result in the product of sodium carbonate .

Another common application of calcium chloride drying agent is in products that are intended to absorb moisture from the air. Some examples of these products are DampRid and Dri-Z-Air. For applications as a packaging aid, calcium chloride drying agent has been approved by the FDA for purposes of ensuring dryness of the package contents .

In its most common application, calcium chloride drying agent comes in solid form, and works as an absorbent. Other types of desiccants commonly used for specialized purposes may come in liquid or gaseous form as well. These types of desiccants commonly work via other processes, such as by chemically bonding the molecules in water.

Of course a drying agent will have to display performance efficiency as well. The quality of a particular desiccant in this regard can be determined by measuring the ratio or percentage of water that it can store relative to its mass.

Back to Top

Applications of calcium chloride

Some of the more common applications of calcium chloride drying agent are:- brine for refrigeration facilities

- ice and dust control

- desiccation

OCalcium chloride is often used in the process of manufacturing the desiccant drying tubes commonly used in packaging. For this particular application, calcium chloride drying agent is typically applied onto kelp, which result in the product of sodium carbonate .

Another common application of calcium chloride drying agent is in products that are intended to absorb moisture from the air. Some examples of these products are DampRid and Dri-Z-Air. For applications as a packaging aid, calcium chloride drying agent has been approved by the FDA for purposes of ensuring dryness of the package contents .

Calcium chloride used as a desiccant

Calcium chloride is particularly suited for use as a desiccant because of its hygroscopic qualities. Substances that have these qualities work to induce or to sustain a condition of dryness in a local vicinity, which is typically a sealed container.In its most common application, calcium chloride drying agent comes in solid form, and works as an absorbent. Other types of desiccants commonly used for specialized purposes may come in liquid or gaseous form as well. These types of desiccants commonly work via other processes, such as by chemically bonding the molecules in water.

The drying effect of calcium chloride

Calcium chloride drying agent is typically used in order to remove humidity that would otherwise destroy a product or cause to it deteriorate significantly. In addition to calcium chloride drying agent, some of the more commonly used desiccants are silica in gel form, charcoal in activated form, calcium sulfate and calcium chloride, a specific type of clay called montmorillonite, and molecular sieves.Important qualities of a desiccant

Some of the most important qualities of drying agents are chemical reactivity and efficiency at drying. These factors are particularly significant when determining the feasibility and practicality of using calcium chloride drying agent. When used for preserving, drying agents will have to be either stable or inert in a chemical sense. Commonly used drying agents that have these qualities are silica gel, chalk and desiccants manufactured from certain types of clay.Of course a drying agent will have to display performance efficiency as well. The quality of a particular desiccant in this regard can be determined by measuring the ratio or percentage of water that it can store relative to its mass.

Back to Top

Drying Agent

Drying Agent Resources

Sponsored Links